Semi-Industrial Reverse Osmosis System -

250LPH/2000GPD

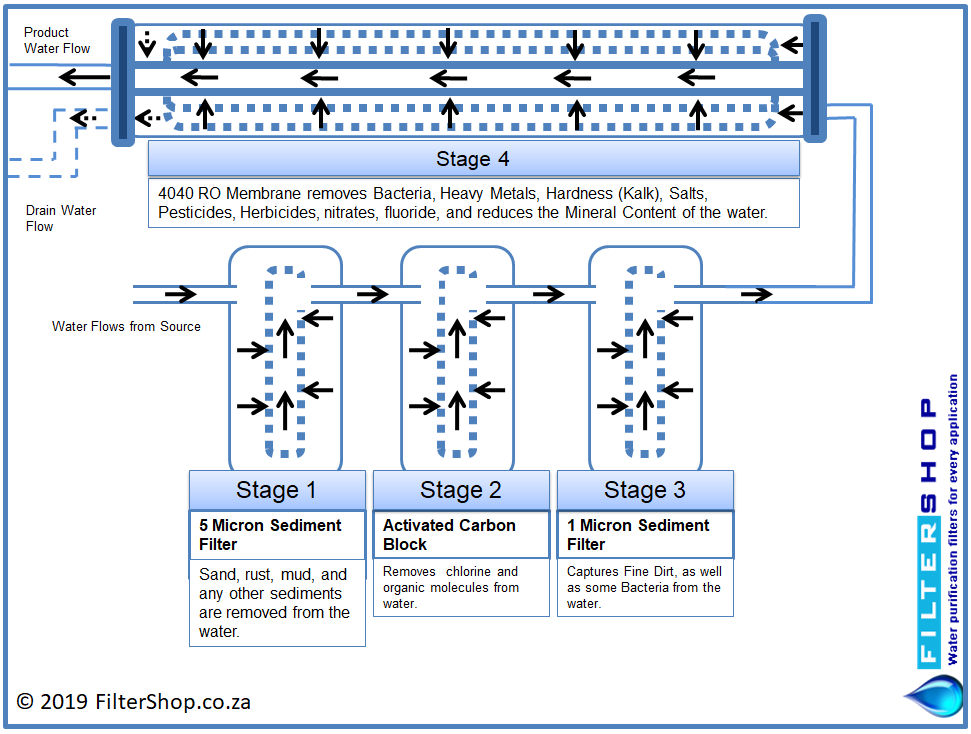

The Reverse Osmosis (RO) system is one of the most complete systems available. It has the ability to eliminate up to 99.8% of harmful contaminants in water such as bacteria, viruses, lead, radium, chlorine, and arsenic. It makes use of multi-stage filtration technology.

With the RO system, you can rest assured that your drinking water is clean, clear and healthy.

The Semi-Industrial Reverse Osmosis System is designed for low TDS feed water design Feed TDS <1500ppm.

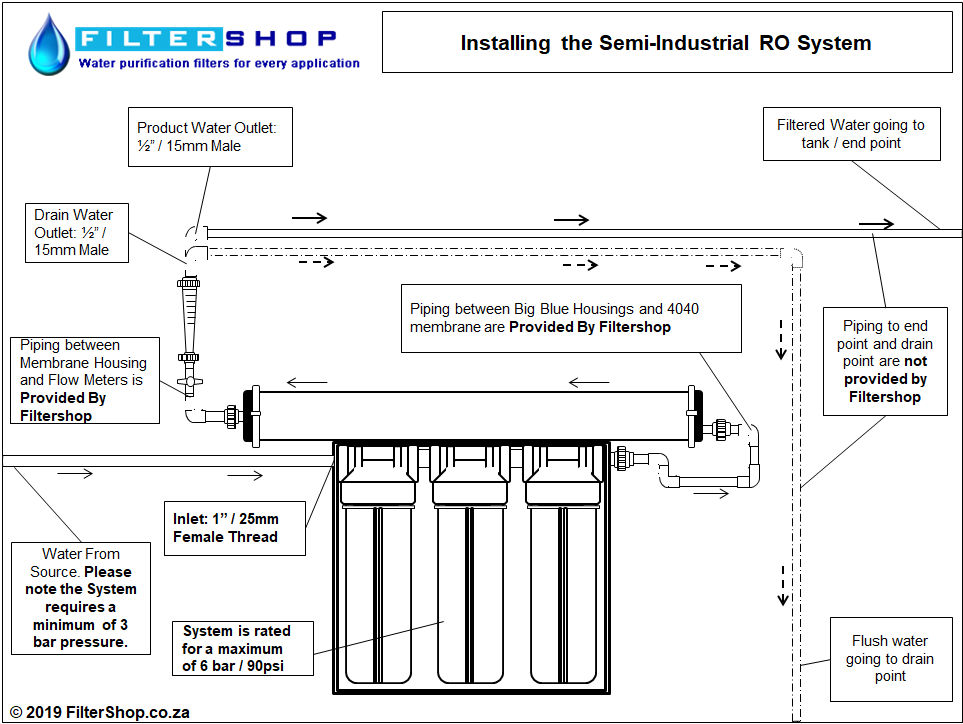

Please note that the Semi-Industrial RO system does not come standard with a pressure pump. The Semi-Industrial RO system requires a minimum of 3 bar water pressure to operate, if your source water does not have adequate water pressure then we would recommend installing a booster pump before the system.

Important: Please note that we strongly recommend having your source water tested, before purchasing any type of industrial Reverse Osmosis (RO) system. As the quality of the source water will directly affect the production rate of the RO system, the Life Span of the filters, the quality of product water produced, as well as the effectiveness of the RO system against potential contaminants in the source water. Filtershop cannot offer any kind of guarantee on the effectiveness of the RO system if no source water test results are supplied before purchasing the RO system.

- The Semi-Industrial RO System is rated for 250 Litres Per Hour Maximum Flow. However, keep in mind that the actual production rate will depend on the quality of the source water, and water pressure. In practice, you will typically find that an RO's production rate will be 30 to 70% of its maximum rated capacity. Please note that in situations with very poor source water quality (such as high mineral content) the production rate can be even lower.

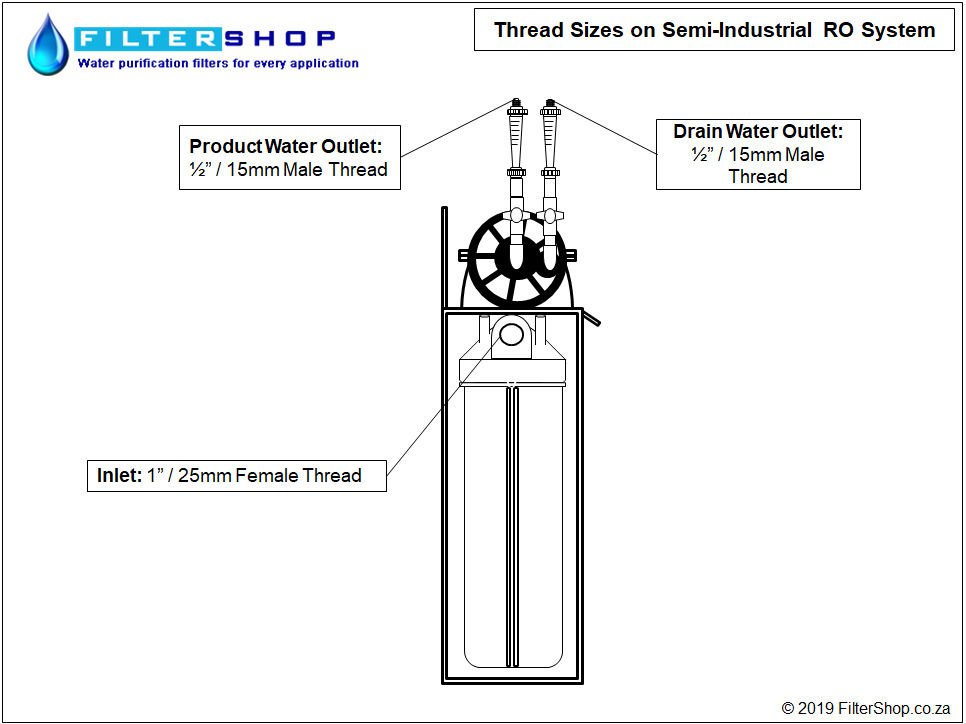

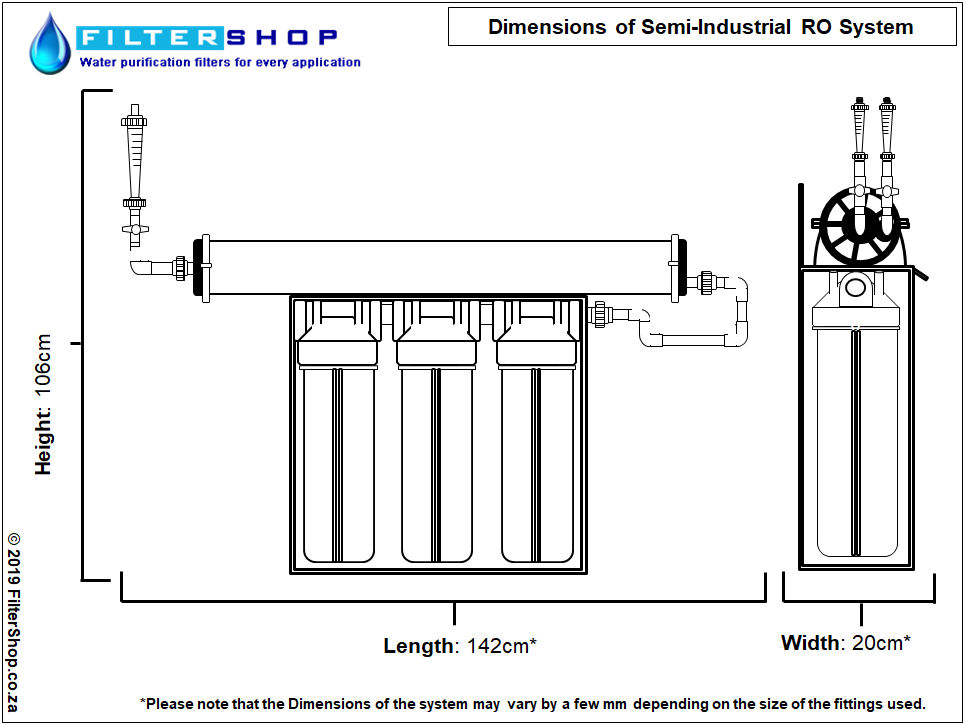

- The Semi-Industrial RO System comes with a stainless steel frame, with three big blue housings. The Membrane housing is typically stainless steel however, please note that if the stainless steel housings are out of stock, the FRP Membrane housings (White) will be used.

- The Semi-Industrial RO System comes with inline flow meters on both the product water and drain water outlets, there are also manual valves, which allow you to control the flow rate out both the drain and product water outlet. Keep in mind that the more drain water is allowed out, the lower the mineral content in the product water. And if there is less drain water, then the high the mineral content in the product water.

- Please note that the drain must never be fully closed, the RO membrane must flush itself as it operates (runs) to remove the minerals and contaminants captured on the membrane’s surface. Failure to flush the membrane as it filters, will damage the membrane and greatly reduce its life span.

- The System comes with a handheld TDS (Total Dissolved Solids) Meter, which will allow you to test and monitor the product water being produced by the system. This will help to fine tune the throttling of the manual valves to get the best wastewater to product water ratio, for the desired mineral content.

- The Semi-Industrial RO system does not come standard with a pump and works on the pressure coming from the source water. The minimum recommends working pressure is 3 bar, and the system is rated for a maximum of 6 bar. If your incoming pressure is below three bars, then we recommend installing a booster pump before the system.

- Please note that the Semi-Industrial RO System is built on demand, if there is not a unit in stock then construction time is 2 to 3 working days from when payment is received.

Things to Keep In Mind about RO Systems

RO Plant flow ratings

- The production rating of all the RO plants is based on an ideal quality source water, so in situations, with low to poor quality source water the actual flow rate produced by an RO plant can be as low as 30 to 70 % of the rated Maximum capacity. So, in other words, a 100 Litre Per Hour plant typically will produce between 30 to 80 liters per hours in real-world applications.

- Please also note that during flushing procedures the RO plant will require 3 times the rated output of the RO from the source. (For example, a 100 liter per RO plant will require a minimum flow rate of 300 Litres per hour from the source).

- Keep in mind that none of the RO plants are designed to be or should be run 24 hours a day, as this will lead to damage of both the components and membranes.

- The RO plants require a minimum of 2 – 3 bar pressure from the source water, if you are using gravity feed then you should consider putting a pressure pump In to feed the RO system.

Waste Water

- As the RO process filters water to such a fine level, the membranes need to flush themselves as they run to remove the contaminants and minerals caught on them. This flushing results in wastewater, which will go straight down the drain.

- On the smaller size industrial RO plants, the wastewater to product water ratio is typically between 1:1 and 2:1. So for every 1 Litre produced by the reverse Osmosis plant between 1 to 2 liters will be used to flush the membranes and goes down the drain.

- With the large-scale RO plants, the wastewater to product water is typically between 1:2 and 1:1. So for every 1 liter of product water produced by the plant between .5 to 1 liter of water is used to flush the membranes and goes down the drain.

- Please keep in mind that the exact wastewater to product water ratio will depend on a number of factors such as the quality of the source water and what quality of product water you are trying to produce. Normally the lower the TDS you are trying to produce from the RO plant, the high the wastewater ratio will be.

- The RO Plant requires a minimum of 2 bar incoming water pressure.

Product water quality

Typically with most municipal supplies, the Industrial RO plants should produce product water with a TDS of less 10. However, please note that this will depend on the quality and TDS of the source water. Higher source water TDS will lead to a much higher TDS level in the final product water.

Installation of Semi-Industrial Reverse Osmosis (RO) System

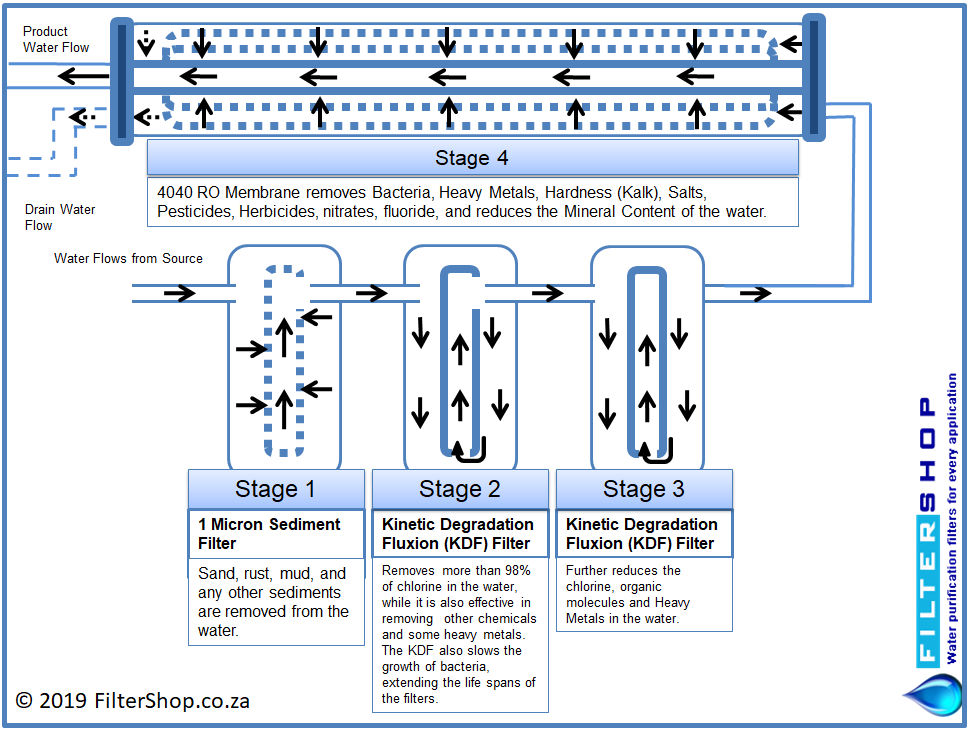

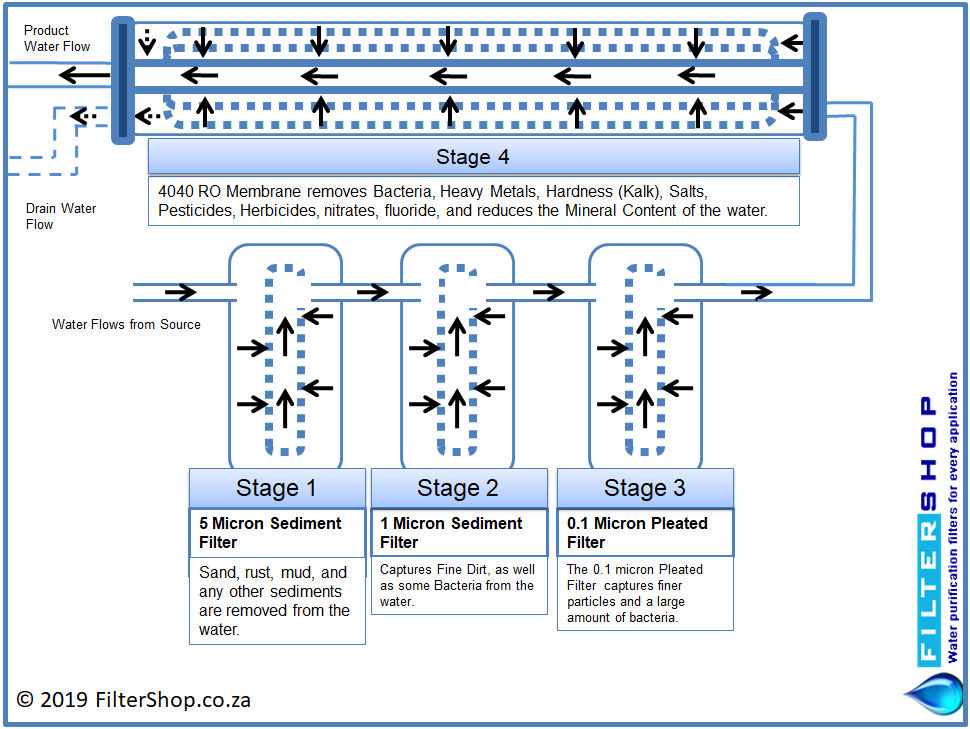

Pre-filter Set Options

There are several different combinations of Filters available for the Semi-Industrial Reverse Osmosis (RO) System. Please see below some information on the different sets, and what each of the filers removes from the water.

Filter Set Option 1: 5 Micron, Activated Carbon Block, & 1 Micron

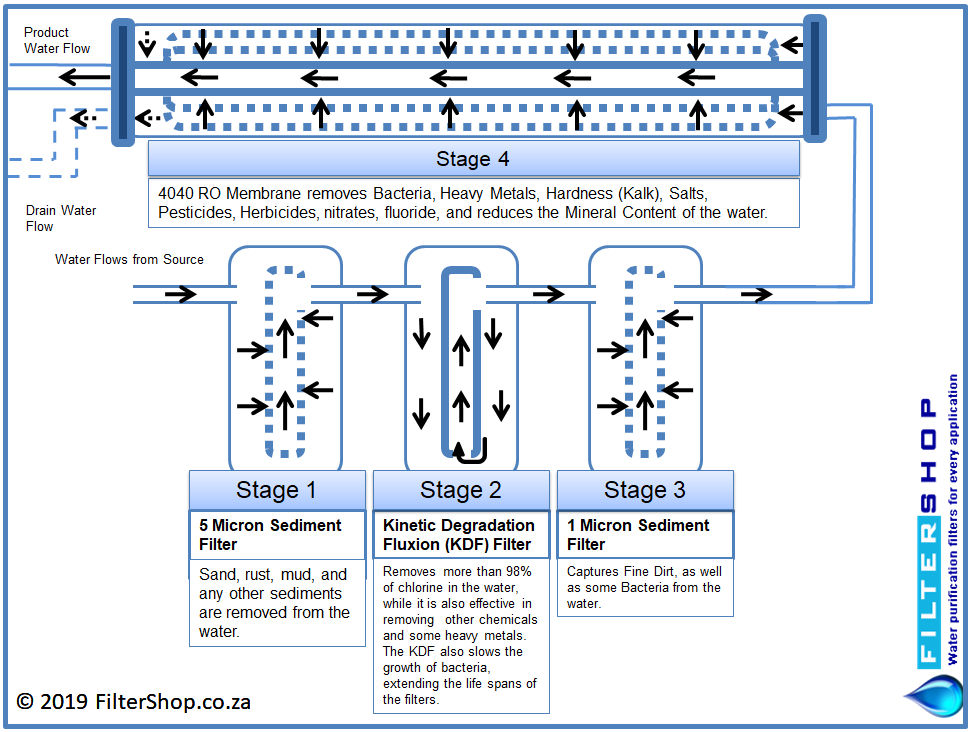

Filter Set Option 2: 5 Micron, Premium KDF Cartridge, & 1 Micron

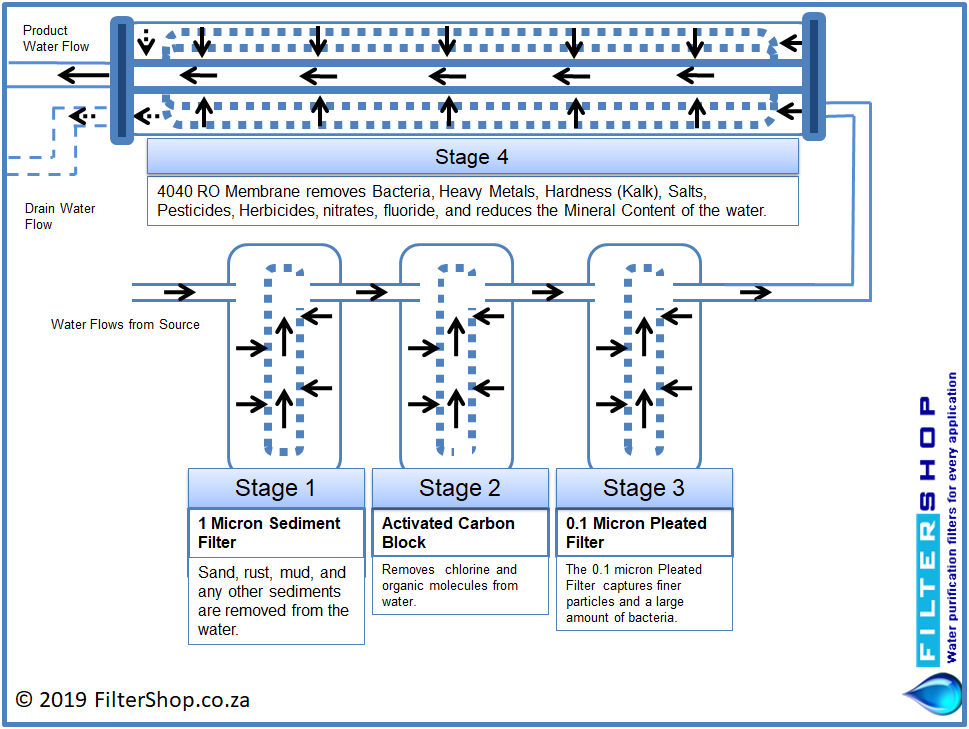

Filter Set Option 3: 1 Micron, Activated Carbon Block, & 0.1 Micron

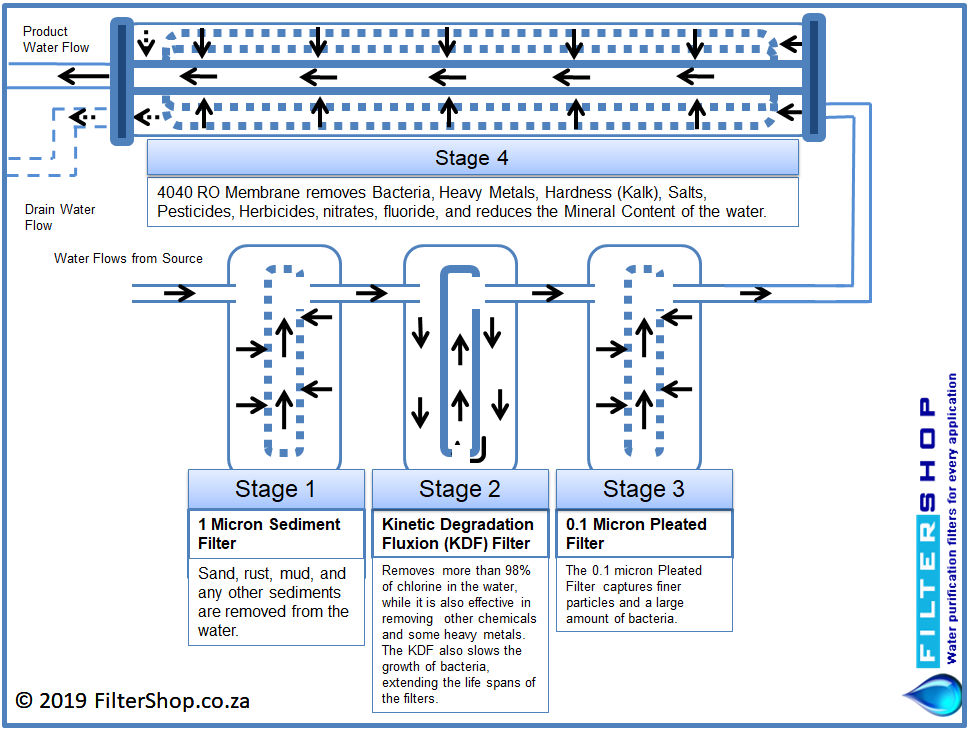

Filter Set Option 4: 1 Micron, Premium KDF Cartridge, & 0.1 Micron

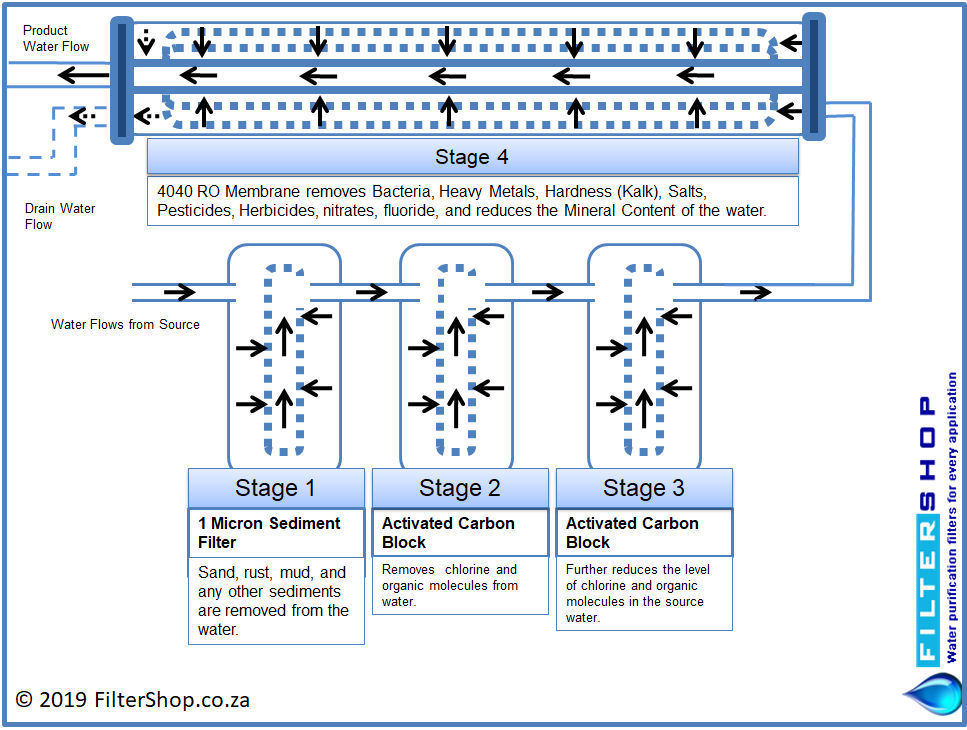

Filter Set Option 5: 1 Micron, & 2 x Activated Carbon Blocks

Filter Set Option 6: 1 Micron, & 2 x Premium KDF Cartridges

Filter Set Option 7: 5 Micron, 1 Micron, & 0.1 Micron

*Please keep in mind that this option will not remove any chlorine from water, and is not recommended for municipal source waters.

PVC Threaded and Glue Fittings

PVC(Polyvinyl chloride) fittings are used to connect sections of pipes or tubes, adapt to different sizes or shapes, and control the flow of water. There are two predominant types of PVC fittings namely PVC Glue Fittings and PVC Threaded Fittings. The difference between the two is that PVC Glue Fittings result in permanent joints and PVC Threaded Fittings are semi-permanent and can be replaced. PVC Glue fittings are joined with primer and cement- a chemical solvent that melts the surface of the PVC and then quickly re-hardens to fuse the pieces together. This results in an airtight, leak-proof bond similar to what you get with welding metal. An example of such a fitting is a PVC Glue Reducing Socket which is used to join together two pieces of PVC pipes with different diameters. Another example would be a 90 Degree Elbow which is used to connect two pipes of the same diameter at an angle of 90 degrees.PVC Threaded fittings utilize a simple threaded connection whereby replaceable 'male threaded' are screwed into 'female threaded'.Male threads have a thread on the outside of the fitting and female threads have a thread on the inside. When you thread the fitting in, it compresses against the other threads.PTFE tape is used to thread these together and the proper way to assemble threaded fittings is to finger tighten, then add one to two turns but no more. An example of a threaded fitting is a Reducing Nipple Male Threaded which is used to connect between two female threads of different diameters.

Link To PVC Fittings