Gold Double Stage Home System

The Double Stage Home Water Filtration is a simple and inexpensive way of removing unwanted particles from a water supply.

Depending on the Filter Set You Select on the Double Stage Big Blue System, the system may also remove chlorine, heavy metals, and some bacteria from the source water.

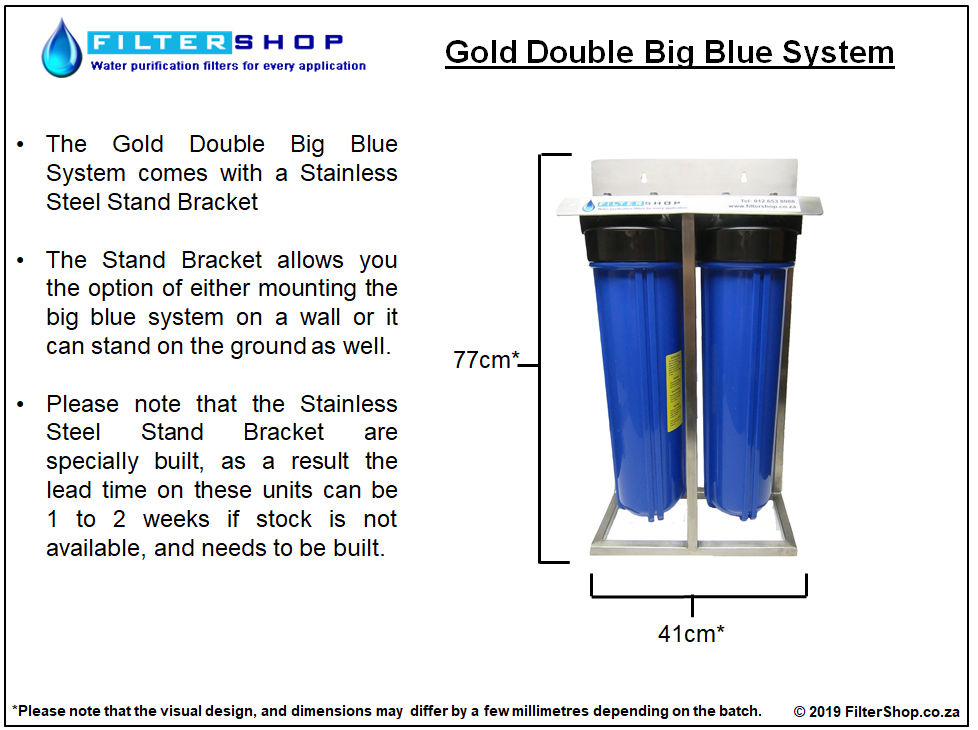

Please note that the construction time on the Double Stage system on a Stand is 2 to 3 working days, from when payment is received.

Benefits:

- All the water supplied to your house is filtered

- Removes chemicals such as chlorine

- Filtrated water tastes and smells great

- Preserve the natural minerals in the water

- No water wasted during filtration

- Low maintenance

- Relatively low filter replacement cost

- No electricity required

- Large filtration capacity

- Low-cost filtration solution

Keep in mind:

- These systems are not ideal for situations with heavy bacteria levels. while the 1 Micron and 0.2 Micron Filters will capture some bacteria, we would recommend that you would rather want to consider a more advanced filtration system, such as the Complete Home Ultra Filtration (UF) Systems or Complete Home Ultra Violet (UV) Systems.

- Minerals and pesticides are too small to be removed by the filters in this filtration unit.

- You will require some plumbing knowledge and experience to install the system successfully.

- These systems typically filter water at a peak flow rate of 2400 liters per hour.

- The Filter housings have a maximum operating pressure of 90 psi. If you suspect that your water pressure will at any time exceed 80 psi, a pressure regulator MUST BE INSTALLED before the filter housing. This action will guard against the water pressure exceeding the maximum pressure rating. It is recommended that the pressure regulator is set at 70 psi or less.

- Protect the filter housing from freezing, as this can cause the housing to crack.

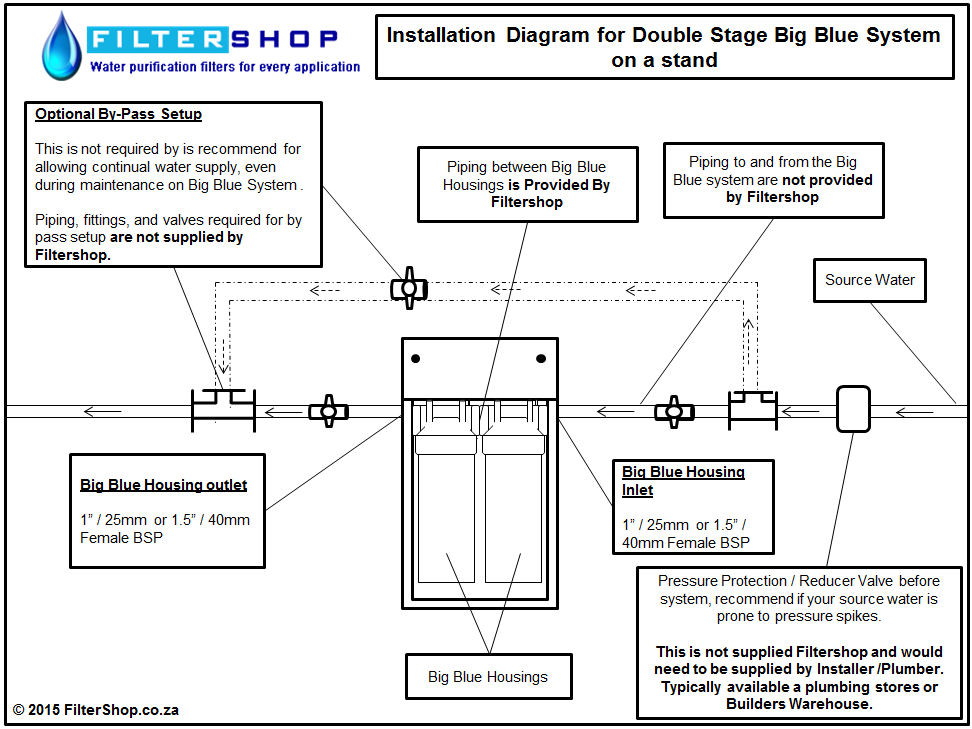

Installation of the Double Stage Big Blue System on a stand

Filter Set Options

There are several different combinations of Filters available for the Double Stage Big Blue Systems.

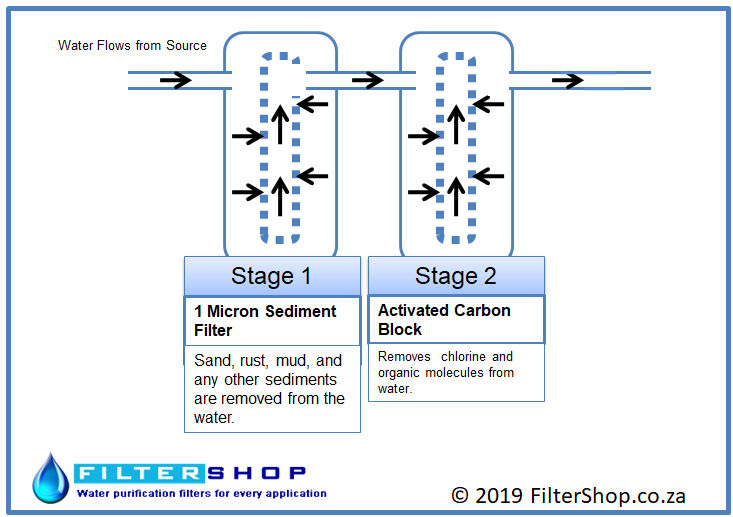

Filter Set Option 1: 1 Micron, & Activated Carbon Block

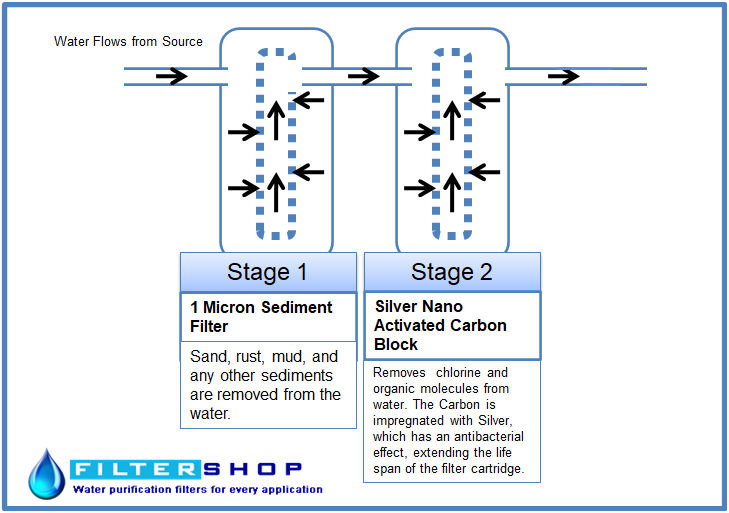

Filter Set Option 2: 1 Micron, & Silver Nano Carbon Block

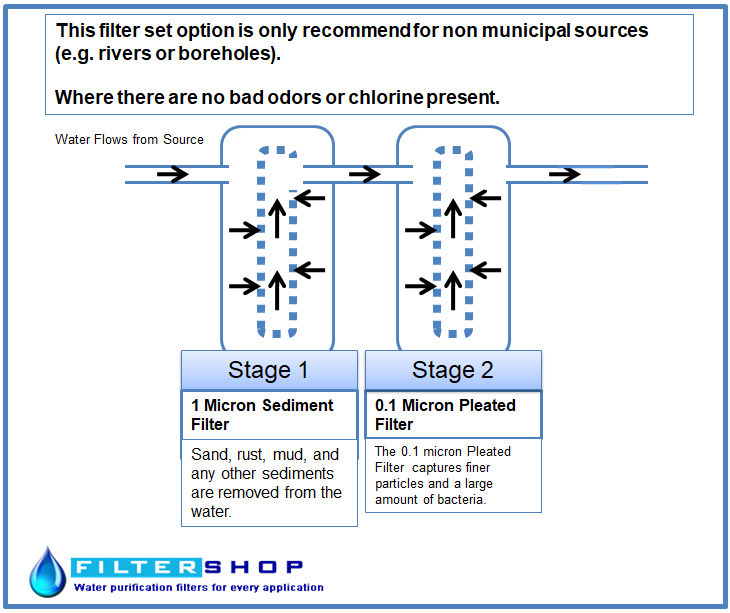

Filter Set Option 3: 1 Micron, & 0.1 Micron

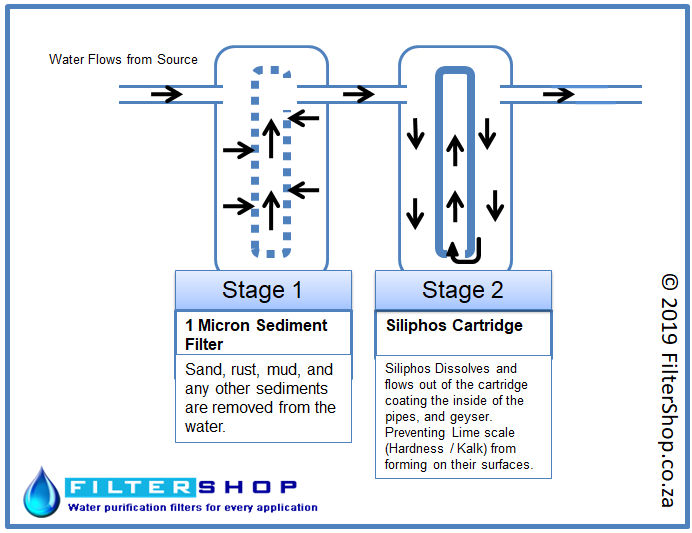

Filter Set Option 4: 1 Micron, & Siliphos Cartridge

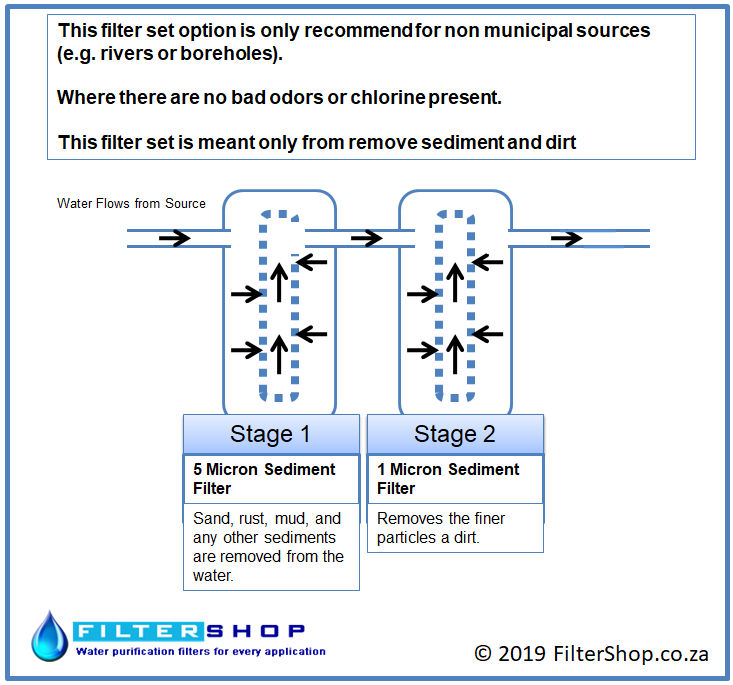

Filter Set Option 5: 5 Micron, & 1 Micron

Additional Options

Change Standard 1 Micron Melted Spray to Antibacterial Option

The Melted Spray Antibacterial filters like the standard melted Spray type are designed to capture dirt, sediments, visible particles, and bacteria.

However, the Melted Spray sediment filters have had a silver ion additive added to their material, which creates a bacteriostatic function to inhibit the growth of bacteria on the surface of the filter, helping to ensure healthier product water and a longer life span of the filter.

This option is ideal for source waters that have a very high bacterial / organism count and will help to extend the life of the filter.

Change Nominal 0.1 Micron to Absolute 0.1 Micron Pleated Filter Option

If you select a filter set with the 0.1 Micron Pleated Filter then you will have the option of either a "Nominal" or "Absolute" Pleated Filter for the 0.1 Micron.

Most sediment filter cartridges such as the standard 0.1 Micron Pleated Filter, have what is referred to as a nominal filter rating. Essentially what this means is that the micron rating of a filter is the approximate "average" size (diameter) of the pores on its surface and within the cartridge itself. It is generally accepted that filters with nominal filter ratings will retain (trap) around 85% of the particles equal or greater in size to the stated micron rating.

An "Absolute" filtration rating means that the filter material has been specifically manufactured, and passed lab testing to ensure that 99.9% of the particles larger than the stated micron rating will be captured (trapped) on the surface or within the filter itself. In the case of our 0.1 micron Absolute Filters, this means that you will get the most effective removal of bacteria and organisms possible with 20" Big type Filter Cartridges.

By-pass piping setup

Adding a bypass to the system allows you to divert the flow of water around the system if you need to conduct maintenance on the system.

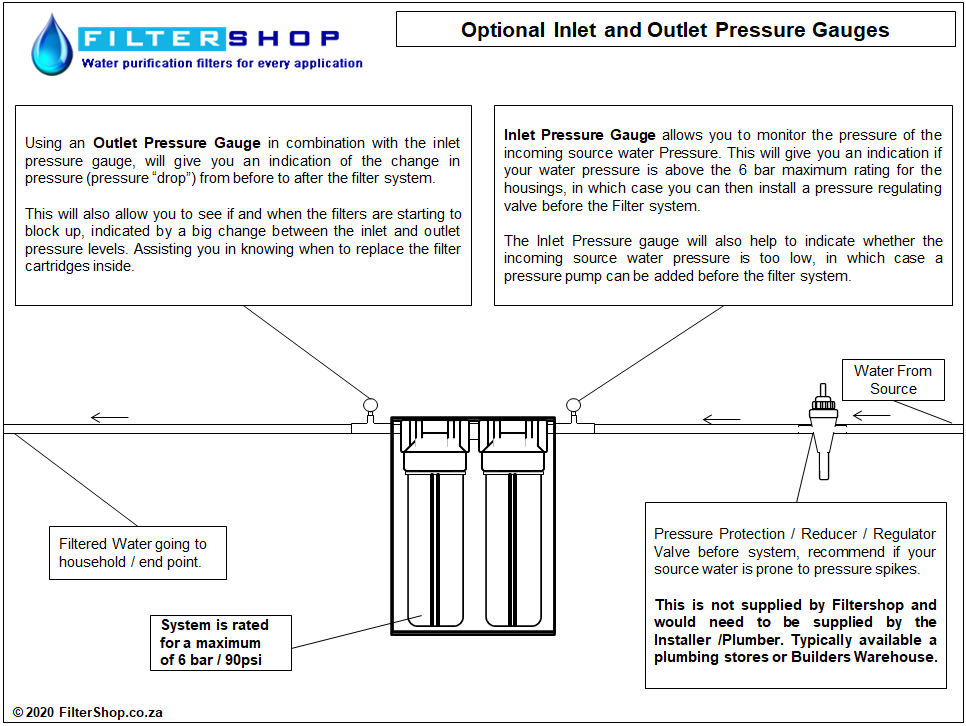

Optional Inlet and Outlet Pressure Gauges

Inlet Pressure Gauge allows you to monitor the pressure of the incoming source water Pressure. This will give you an indication of your water pressure is above the 6 bar maximum rating for the housings, in which case you can then install a pressure regulating valve before the filter system.

The Inlet Pressure gauge will also help to indicate whether the incoming source water pressure is too low, in which case a pressure pump can be added before the filter system.

Using an Outlet Pressure Gauge in combination with the inlet pressure gauge will give you an indication of the change in pressure (pressure “drop”) from before to after the filter system.

This will also allow you to see if and when the filters are starting to block up, indicated by a big change between the inlet and outlet pressure levels. Assisting you in knowing when to replace the filter cartridges inside.

Please note that pressure gauges are built to order, construction time is 2 to 3 working days.

PVC Threaded and Glue Fittings

PVC(Polyvinyl chloride) fittings are used to connect sections of pipes or tubes, adapt to different sizes or shapes, and controlling the flow of water. There are two predominant types of PVC fittings namely PVC Glue Fittings and PVC Threaded Fittings. The difference between the two is that PVC Glue Fittings result in permanent joints and PVC Threaded Fittings are semi-permanent and can be replaced. PVC Glue fittings are joined with primer and cement- a chemical solvent that melts the surface of the PVC and then quickly re-hardens to fuse the pieces together. This results in an airtight, leak-proof bond similar to what you get with welding metal. An example of such a fitting is a PVC Glue Reducing Socket which is used to join together two pieces of PVC pipes with different diameters. Another example would be a 90 Degree Elbow which is used to connect two pipes of the same diameter at an angle of 90 degrees.PVC Threaded fittings utilise a simple threaded connection whereby replaceable 'male threaded' are screwed into 'female threaded'.Male threads have a thread on the outside of the fitting and female threads have a thread on the inside. When you thread the fitting in, it compresses against the other threads.PTFE tape is used to thread these together and the proper way to assemble threaded fittings is to finger tighten, then add one to two turns but no more. An example of a threaded fitting is a Reducing Nipple Male Threaded which is used to connect between two female threads of different diameters.

Link To PVC Fittings