Duplex Water Softener Systems

The Duplex Water softeners are used to remove hardness (also known as calcium, lime, kalk) from water. A water softener is what is referred to as an "ion exchange" system, removing hardness from water by exchanging sodium ions for the calcium and magnesium ions in the water, thus "softening" the water.

The Duplex Water Softeners are designed for applications where a continual supply of water is required, 24 hours a day. With normal single Vessel water softeners (also referred to as simplex softeners), when the water softener runs its regeneration cycle, there is no "product" water being produced by the water softener, as all the water is being diverted to the drain to flush the softening resin. For applications where water is continually required (24 hours a day), this is a problem as for an hour or more there will be no "product" water while the softener runs its regeneration cycle. The duplex softener solves this problem, by allowing "product" water to be continually supplied, even while the water softener is regenerating its resin.

Before purchasing any side water softener system we recommend having the source water tested first, to see both the hardness level in the water and other elements that could reduce the softener's effectiveness, such as sodium, iron, nitrates, etc. Please note that filtershop cannot give a guarantee on our water softener systems if the source water has not been tested before purchasing the softener system.

Please note that these duplex water softeners are designed for domestic or light commercial/industrial purposes. If you have a heavy industrial application, with a much higher flow rate per hour over 24 hours, then we recommend contacting us for a quotation. Please keep in mind that in order to quote you on a large industrial Duplex softener system, Filtershop will require a full water analysis of the source water.

Admittedly the same effect can also be achieved by having two standard-type (simplex) water softeners installed in parallel, and having their regeneration cycles run a different times. This means one softener can run its regeneration process, while the second softener continues to operate. However, a Duplex softener simplifies the whole process by having a single valve head to control both softener vessels, so you only need to program a single valve head, and not two individual valve heads. This also means less power usage, as only a single valve head needs to be plugged in. The duplex Softener would also only require a single brine tank, where two individual Softeners would each have to have their own individual brine tanks, which means you would need to fill both tanks with salt.

What size Duplex Softener should I get?

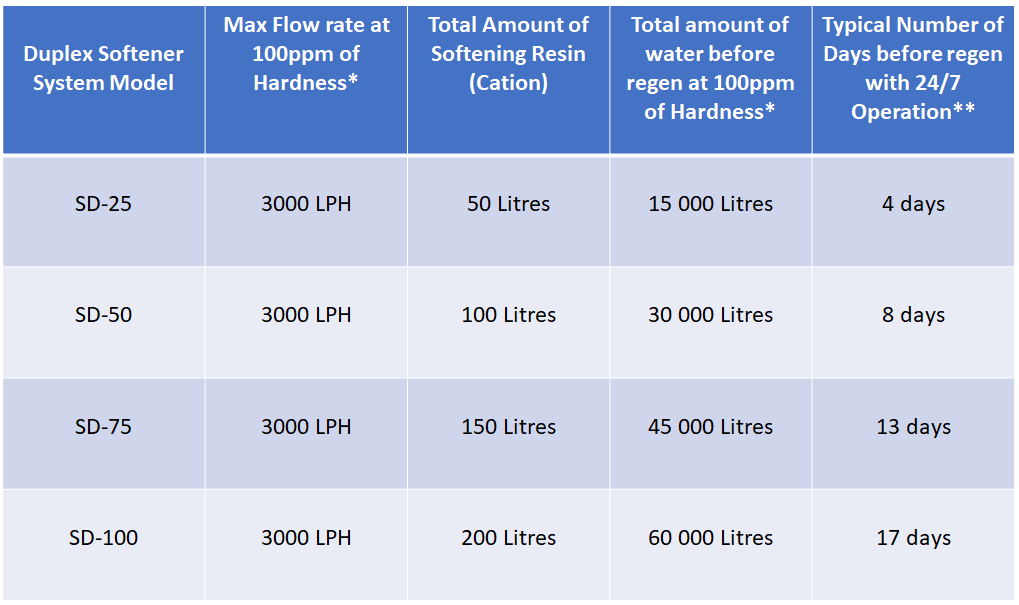

The fact is that all the Duplex water softeners can handle similar flow rates, the difference will be with the effectiveness of the hardness removal and the regularity of the regeneration cycles at higher flow rates. Please note that the table below is simply to act as a very rough guide to how much water a duplex softener can filter when running 24/7, this is based on the assumption that the hardness level in the water is 100ppm (parts per million). Keep in mind that the higher the hardness level (ppm) in your particular source water, the more you will need to reduce the total water and days before a regeneration.

*Keep in mind that while the Max Flow Rate and Total amount of water are based on 100ppm of hardness, there are elements that can influence the effectiveness of the duplex softener units. These include but are not limited to total Iron, Nitrate, and Sodium content in the water. As a result, we always recommend that before putting a water softener unit in place, you have your source water tested to ensure that a softener will work for your particular water's quality.

**If your water source is not running 24/7, then the number of days before regeneration may be increased.

Included in the price:

- 2 x Fibre Glass vessels (Either 25 Litre or 50 Litre or 75 Litre or 100 Litre)

- 2 x Rise pipes

- 2 x Sets of Strainers

- 1 x Duplex Softener Valve Head (F73A / 3000LPH)

- Softener Resin (Cation)

- 100 Litre Brine Tank

- 3/8" Piping (for attaching brine tank)

- First Bag of Salt

- Hardness Testing Strips

Not included in the price:

- Plumbing and installation costs

- Delivery costs (i.e. a courier service)

- Replacement filters

PVC Threaded and Glue Fittings

PVC(Polyvinyl chloride) fittings are used to connect sections of pipes or tubes, adapt to different sizes or shapes, and controlling the flow of water. There are two predominant types of PVC fittings namely PVC Glue Fittings and PVC Threaded Fittings. The difference between the two is that PVC Glue Fittings result in permanent joints and PVC Threaded Fittings are semi-permanent and can be replaced. PVC Glue fittings are joined with primer and cement- a chemical solvent that melts the surface of the PVC and then quickly re-hardens to fuse the pieces together. This results in an airtight, leak-proof bond similar to what you get with welding metal. An example of such a fitting is a PVC Glue Reducing Socket which is used to join together two pieces of PVC pipes with different diameters. Another example would be a 90 Degree Elbow which is used to connect two pipes of the same diameter at an angle of 90 degrees.PVC Threaded fittings utilise a simple threaded connection whereby replaceable 'male threaded' are screwed into 'female threaded'.Male threads have a thread on the outside of the fitting and female threads have a thread on the inside. When you thread the fitting in, it compresses against the other threads.PTFE tape is used to thread these together and the proper way to assemble threaded fittings is to finger tighten, then add one to two turns but no more. An example of a threaded fitting is a Reducing Nipple Male Threaded which is used to connect between two female threads of different diameters.

Link To PVC Fittings