100GPD Filmtec RO Membrane

The Reverse Osmosis (RO) Membrane forms the heart of a Reverse Osmosis System. It consists of a semi-permeable membrane that allows water molecules to pass through but captures 99.8% of all other particles in the water. The RO Membrane removes bacteria, viruses, minerals, heavy metals, and pesticides from the water.

The Filmtec 1812 RO Membranes are designed to work with low-pressure situations with small residential RO systems (such as under-the-counter ROs) or with small purification systems used for applications such as DI (Deionized) water, Laboratories, Hospitals, Battery water, aquariums, offices, ice makers, restaurants, etc. The Filmtec 1812 model membranes work most effectively with source waters that have a TDS of 500ppm or lower (<500ppm).

FilmTec™ Residential Elements features:

- Longer lifetimes can reduce operating costs for OEM’s/brand owners

- NSF safety certification and the ability for NSF data transfer reduce certification costs

- Fully-automated manufacturing that ensures consistent and high-quality elements

- Dry shipping for convenient handling and longer shelf-life

- High-quality elements significantly reduce or eliminate element Quality Control (QC) costs

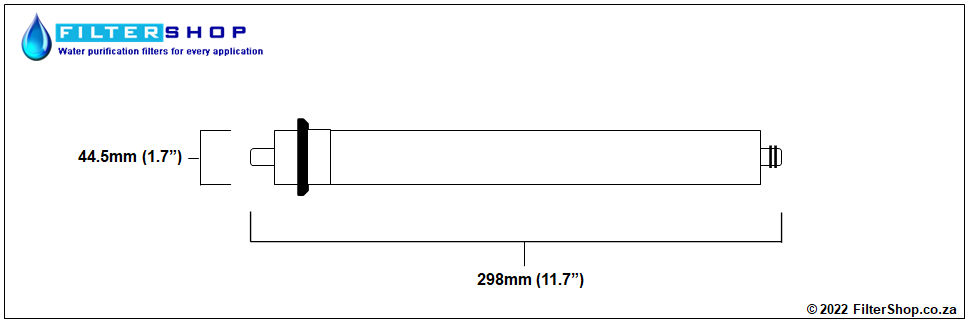

Filmtec 100GPD Membrane Specifications:

- Average Permeated Flow (Product Water): 75GPD / 380LPD*

- Stable Rejection Rate: 90%

- Minimum Rejection Rate: 90%

- Membrane Type Polyamide: Spiral-wound element with Thin-Film Composite

Testing Conditions for Specification rating:

Testing Pressure: 60psi (4 bar)

Testing Solution Temperature: 25°C

Testing Solution Concentration (Softened Tap water) - 250ppm

PH Value of Testing Solution: 7.5

Recovery Rate of Single Element: 15%

Keep in Mind

The average permeated (product) water flow is based on test water consisting of 250ppm of only salt (NaCl) which is one of the easier minerals for the RO membrane to handle. Other elements such as hardness (lime, Calcium/Magnesium) are harder for the membranes to remove, and may reduce the average permeate rate of the RO membrane.

Other elements such as source water pressure and the Total Dissolved Solids (TDS / Total Mineral Content) level can also have an influence on the permeate level produced by the membrane. Typically in real-world situations with municipal or non-municipal source water quality, you will not get the same quality and/or pressure as the "testing conditions" used to rate the membranes. So, in most applications, you will likely find that the actual permeate flow rate of the RO membrane is between 30 to 80% of what has been rated.

Operating Limits for the membrane:

Maximum Operating Temperature: 113°F (45°C)

Maximum Operating Pressure: 150 PSI (10 bar)

Maximum Feed Flow Rate: 2.0 GPM (7.6 lpm)

pH Range, Continuous Operation: 2 – 11

pH Range, Short-Term Cleaning: (30 min.)b 1 – 13

Maximum Feed Silt Density Index (SDI): 5

Free Chlorine Tolerance: < 0.1 ppm

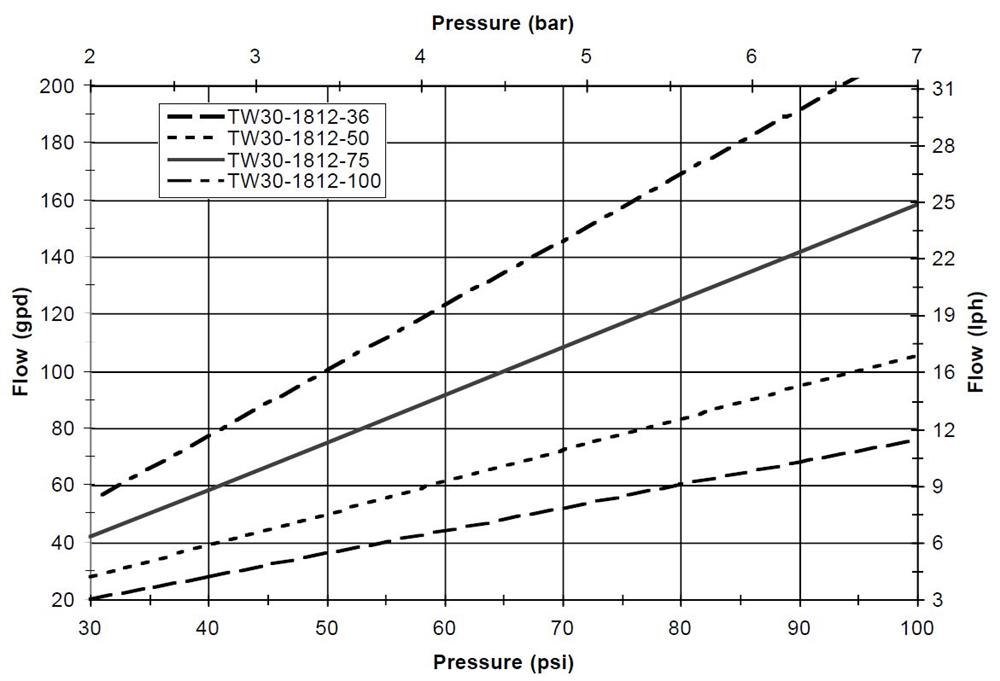

Impact of Pressure on Product (Permeate) water rate*:

*Please note that the above graph is with the assumption the temperature of the water and recovery remain constant.

*Please note that the above graph is with the assumption the temperature of the water and recovery remain constant.